Challenge

A proper and timely response to emergencies, correct manipulations of complex equipment, acceleration of personnel trainings for high-stress processes – all of these scenarios regularly encountered for modern production facilities. Delays in the start-up of equipment or even the entire plant due to a limited number of training points, insufficient involvement of participants, limited abilities to simulate the required scenarios are the most common problems for real life education. Choosing the right training option can become tricky because of limited communication in the real world, medical constraints, personnel safety, considerable expenses, etc.

Technology solution:

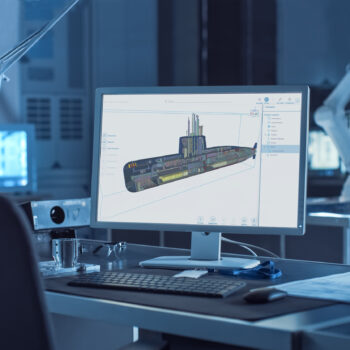

Immersive trainings place individuals in an interactive 3D learning environment, either physically or virtually, to replicate possible scenarios or to teach particular skills or techniques. Open Cascade proprietary technology allows scenes to be prepared for VR and other types of immersive training, simplifying heavy 3D data and optimizing it for any specific hardware requirement or any required workflows. Highly professional immersive virtual reality capabilities allow personnel to be trained to act quickly, decisively and accurately in a real emergency, quality control, or maintenance and repair operations.

Possibility to realize different scenarios gives the customer opportunity to train personnel even before facilities’ launch. Virtual 3D trainings can be adopted to any changes in digital mockup thanks to the established 3D continuity. Leveraging its unique 3D visualization and processing capacities, Open Cascade helps different industries to benefit from existing 3D data by offering tailored solutions for immersive trainings.

Upon request from the client, the solution can be deployed locally on corporate computers or in a cloud-based web architecture. 3D replicas create virtual yet realistic environments that enable remote trainings for geographically dispersed teams.

Business value

- The proper usage of immersive learning technologies increases employees’ productivity.

- Minimization of training and development costs during design or operational changes with 3D continuity across all plant data.

- Minimization of project risks by avoiding delays during commissioning and plant start-up with comprehensive trainings for operators, field engineers and maintenance technicians.

- Delivering of accelerated learning that is sustainable, effective, and on budget with AR / VR technology.

- ROI and profitability increase by making the usage of resources more efficient while maintaining a high level of safety of operations.